Introduction¶

The last decade has seen an explosion of the open source community around 3D printing. Many great softwares have emerged, that are simpler, faster and cheaper to use. I found one of them particularly promising and decided to adapt it for plasma cutting. This was Klipper and we will see why it is so special.

Klipper for plasma is a modified version of the 3D printing controller Klipper. Therefore, before starting I want to say a big thank-you to Kevin O’Connor in particular and all contributors of Klipper for this brilliant work.

Architecture¶

As opposed to most controllers, Klipper has a distributed architecture. The high level logic stands on a PC, while the real-time stuff is handled by a microcontroller board (MCU). By doing this, it combines benefits of both PC-only and MCU-only architectures.

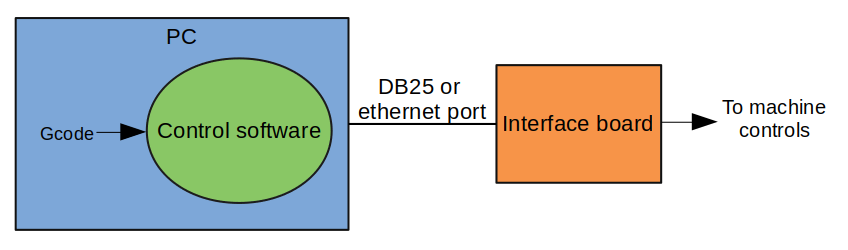

PC only architecture¶

LinuxCNC and Mach3 for example are PC-only, meaning their operating systems (Linux and Windows) use a real-time kernel. This is a powerful, but complex solution. Handling real-time internally also implies to use real-time capable ports to control the machine. This is the reason why they use parallel ports or sometimes ethernet, instead of USB which is not compatible by design. With 3D printers having paved the way for simpler machine control, I now believe that relying on a specialized operating system should be reserved to very complex machines.

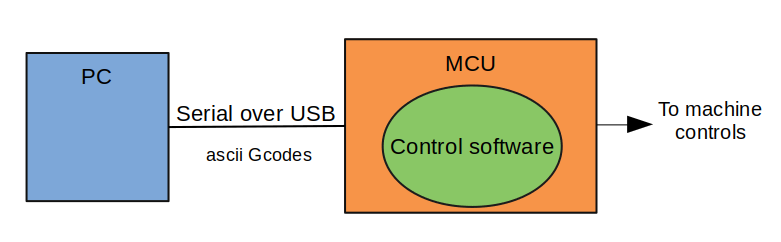

MCU only architecture¶

On the other side, there exist MCU-only architectures like Marlin or Grbl. They rely solely on the MCU. They works fine in most cases, but can struggle to run smoothly on slower boards (8 bits AVR) when adding features like THC. It was the case for Plasmarlin, a fork of Marlin I previously made for plasma. Moreover, these implementations generally use plain ASCII to receive Gcodes and respond. Which is not particularly convenient when having to stream high frequency data to monitor THC for example.

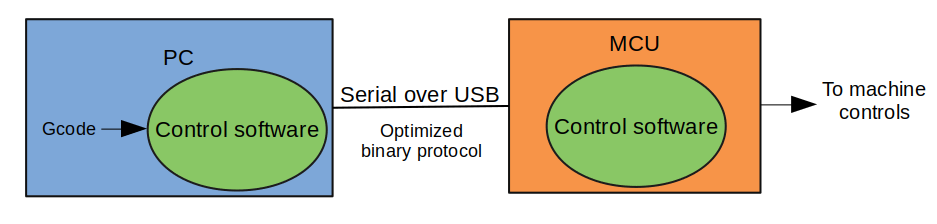

Hybrid architecture (Klipper)¶

For its part, Klipper combines the PC’s performances and the simplicity of MCUs. It can be compared to a PC sound card. The PC sends sounds to be played soon, without concern for timing. Then, the sound card is in charge to play it when perfect time has come, without knowledge of the complete song.

This way, there is no more need for real-time OS and particular ports, just USB. In addition, all complex calculations are done on the PC, meaning even a good old Arduino Mega can achieve great performances. Also, Gcodes are parsed on the PC side, leaving the field open for an optimized protocol over serial, which gives enough bandwidth for THC monitoring. And by the way it is a free and open source.

Features¶

In addition to the original Klipper features, the following have been to handle plasma cutting.

- Basic torch controls :

Plasma start

Plasma stop

Wait for arc transfer

Arc loss detection once running

- THC (Torch Height Controller) :

Full speed THC with acceleration ramps (no babystepping)

Virtual Z limits for THC

Minimum feedrate threshold to pause THC and prevent torch to dive during slowdowns

Future¶

Dynamic control of current and pressure for compatible Hypertherm cutters (Powermax 45XP/65/85/105/125) through RS485 extension board. Controlling the current on the fly allows to keep a constant kerf width when slowing down in corners. It is generally reserved for industrial machines, thus it is a kind of Graal for THC.